Nikola, America’s favorite zero-emissions truck brand, released its first Sustainability Impact Report. This report provides a comprehensive picture of Nikola’s environmental and social initiatives and explains their progress toward sustainability goals.

Nikola owns battery-electric vehicles (BEVs) and hydrogen fuel cell (FCEV) Class 8 trucks, designed specifically to make the environment safer and cleaner. Most significantly, HYLA’s hydrogen refueling ecosystem offers a robust hydrogen infrastructure to support the shift to sustainable fuel sources.

Driving Towards a Zero-Emission Future

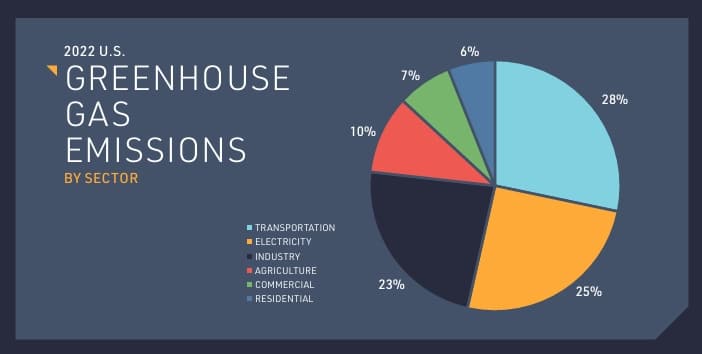

The Environmental Protection Agency (EPA) reports that transportation generates around 28% of direct U.S. greenhouse gas (GHG) emissions. Medium- and heavy-duty trucks alone account for about 23% of these emissions. However, the EPA also highlighted that with the rise in transportation costs and freight demands, zero-emission vehicles can be a solution for a sustainable future.

So Nikola’s mission is clear: to lead the transition to zero-emission technology across critical routes. Thereby, supporting a climate-friendly future for commercial transportation.

Steve Girsky, President and CEO of Nikola, stated,

“Our focus is on zero-emission technologies and the infrastructure to support them, decarbonizing what has been known as a very ‘dirty’ market segment, Class 8 trucks. Medium- and heavy-duty trucks produce more emissions than passenger cars and rail combined. Our commitment—our mission, really—to improving air quality, avoiding emissions, and mitigating our contributions to climate change is why most of us work for Nikola. What we are most proud of, besides our dedicated team, is bringing our battery electric truck to market while developing and launching our hydrogen fuel cell electric truck shortly thereafter.”

Nikola’s sustainability report reveals an interesting piece of information. The company was founded to tackle transportation emissions, specifically. In addition to its net-zero goals, it prioritizes drivers’ health, safety, and community well-being where Class 8 trucks operate.

The truck giant strongly believes that zero-emission transportation is achievable, which is why the company aims to expand its impact throughout the nation.

Environmental Impact and Greenhouse Gas Emissions

Nikola recognizes the risks of climate change and the opportunities that proactive measures offer. The company has taken the following actions to address these risks and capitalize on opportunities:

- Investment in clean technology and innovation

- Measurement and identification of emission sources

- Commitment to renewable energy and energy efficiency in operations

- Installation of EV charging infrastructure for Nikola trucks and employees

- Adoption of circularity principles and waste diversion strategies for improved sustainability

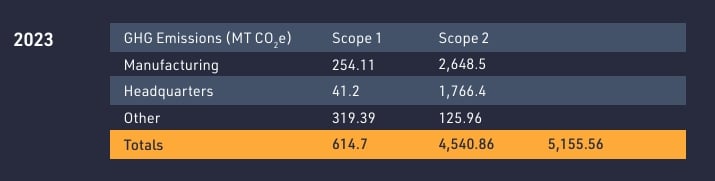

In 2023, Nikola’s total emissions (Scope 1 and Scope 2) were 5,155.56 MT CO₂e.

Hydrogen Trucks Hit the Highway

In Q4 2023, the company introduced hydrogen fuel cell electric trucks on the road in North America. By year-end, 42 trucks were manufactured, with 35 delivered to dealers and seven retained for ongoing testing and fleet demonstrations.

Early in 2024, the first HYLA modular refueling station was launched in Ontario, California, alongside a new partnership with FirstElement Fuel to offer hydrogen fueling solutions in both Northern and Southern California, including Oakland.

Nikola views both battery electric trucks powered by the grid and hydrogen fuel cell electric trucks as essential to reducing emissions in heavy-duty transportation. The company remains dedicated to advancing both vehicle technologies and fueling infrastructure for broad deployment.

The 3-R Approach to Battery Lifecycles

Nikola is committed to a circular economy, where truck and battery components are built to last long. They can be reused and recycled efficiently. The company collaborates with partners to manage materials responsibly at every stage of a vehicle’s life, focusing on durability and resource efficiency.

Regarding battery sustainability, Nikola has a battery circularity policy based on the 3 Rs: remanufacture, reuse, and recycle all pre-consumer and production batteries. Currently, Nikola’s recycling partners recover up to 95% of materials from lithium-ion batteries, aiming to recycle 100% of scrapped batteries. Notably, last year, the truck titan reused 192 metric tons of batteries.

The company also believes in extending battery life as the most sustainable choice. They use advanced vehicle software to receive over-the-air (OTA) updates that improve battery efficiency and extend battery life before recycling.

Waste and Water Management

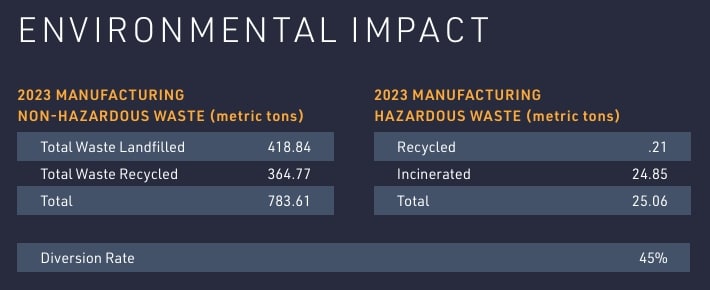

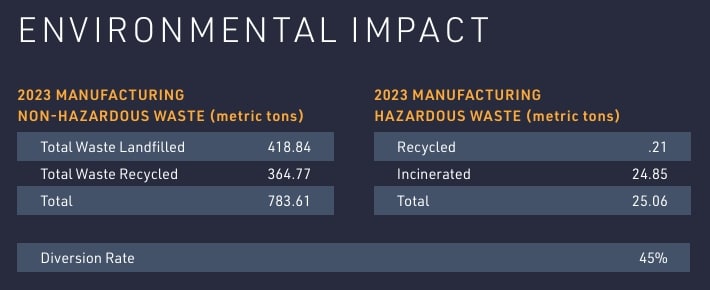

The report also highlights the company’s dedication to improving manufacturing practices and minimizing environmental impact. A Waste Management Committee meets regularly to measure performance and implement strategies. They prioritize recycling materials such as steel, aluminum, lithium-ion batteries, plastic, and cardboard. Additionally, Nikola is mindful of water usage, primarily using water for vehicle quality testing and recycling.

Nikola’s environmental impact data for the last year is as follows:

Resource and Energy Efficiency at Nikola Facility

Nikola is committed to maximizing its resource efficiency and minimizing its manufacturing impact. The 670,000-square-foot Coolidge facility uses advanced eco-friendly technologies, including energy-efficient LED lighting, HVAC systems, and daylighting to cut artificial lighting needs.

Additionally, smart-controlled energy systems optimize resource use, while on-site solar panels and EV charging stations support sustainable practices. Nikola has also deployed electric automated guided vehicles (AGVs) and forklifts to further reduce emissions.

The total energy consumption at the facility is 7,491,559 kWh, of which 771,960 kWh is generated through solar.

By embracing these initiatives, Nikola is paving the way for a more sustainable future.

Disclaimer: Data and visuals- Nikola Sustainability Impact Report